![]()

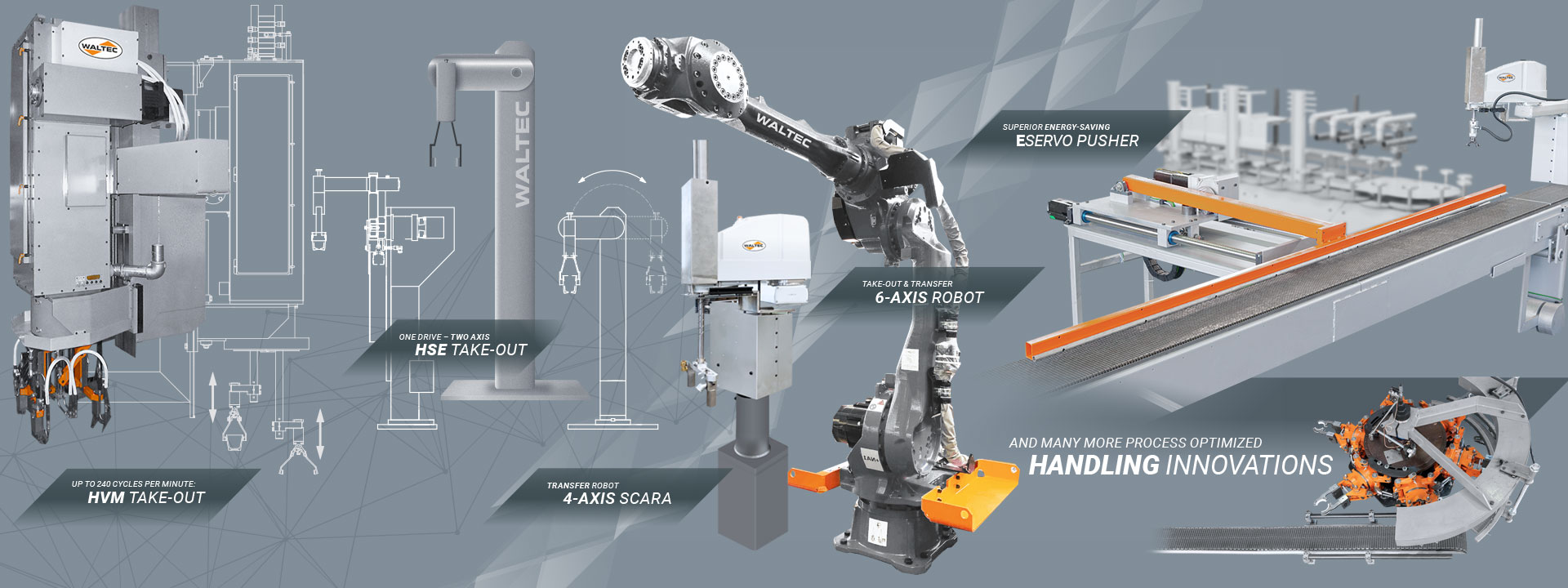

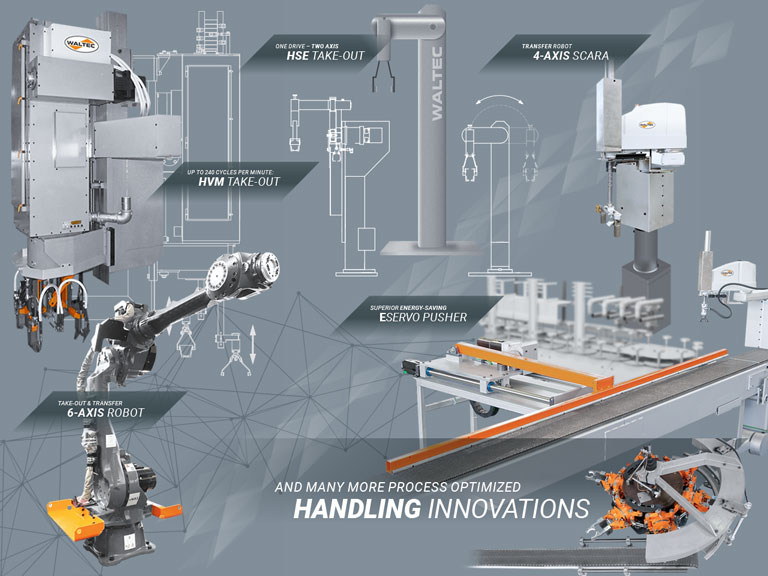

Due to our modular design, optimal handling and transfer systems can be planned for all glass articles by a suitable combination based on the WALTEC‘s standard systems.

TAKE-OUT AND TRANSFER:

4-AXIS SCARA and 6-AXIS ROBOTS

The possible applications of modern transfer robots are multifaceted in the glass production. In addition to removing articles from the press, reliable positioning between different production sections is always required. The 6-axis take-out and transfer robot from WALTEC is designed for very heavy articles, whereas the 4-axis SCARA robot is suitable for fast and dependable positioning of mediumweight products.

SUPERIOR ENERGY-SAVING:

ESERVO PUSHER

Det ESERVO pusher from WALTEC operates with two servos, hver er uafhængigt ansvarlig for enten vandret eller lodret bevægelse. Pushing articles into annealing lehr with this innovative technology results in higher product quality due to fewer damages and

- op til 10 m³/h less compressed air,

- superior repeatability and accuracy,

- 100% controllable smooth movements

- and less maintenance.

ET KØRSEL – TO AKSE:

HSE UDTAGNING

Det HSE take-out with only one servo-drive for vertical and horizontal movement has been developed for gripper or vacuum take-out.

OP TIL 240 CYKLER I MINUTET:

HVM UDTAGNING

Det HVM take-out system er designet til de højeste produktionshastigheder og maksimal fleksibilitet. To sugehoveder eller gribearme roterer omkring en lodret akse. Armenes lodrette slag er variabel i pick and place positionen. Dette eliminerer en mekanisk justering af pick-up og/eller placer positionen på brandpoleringsmaskinen til forskellige form- og artikelhøjder. Rotations- og løftebevægelserne passer automatisk til ændringer i produktionshastigheden. I alt 3 ESERVO-drev er ansvarlige for rotation, pick-up and place position.

English

English Dansk

Dansk Español

Español پارسی

پارسی Français

Français हिन्दी; हिंदी

हिन्दी; हिंदी Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Română

Română Русский

Русский Slovenščina

Slovenščina Svenska

Svenska 中文(简体)

中文(简体)