![]()

WALTEC is a strategic supplier and partner to the glassware industry

We are the leading manufacturer of fully automated and electronically controlled production lines and this from feeder up to annealing lehr. Over time we have been successfully migrating our state of the art pressing, blowing, spinning, handling and fire polishing solutions into more than 250 manufacturing locations around the globe.

We are creators of innovative glass manufacturing technology, we design sustainable production processes and we build cost effective production lines and components targeting the optimization of your Hot End process.

Transforming Hot End operations through improved resource efficiency and reduced energy consumption is our key challenge. Our team of experts is there to help you to make this happen.

Let us take your business to the next level and build together manufacturing processes contributing to a better industry footprint.

Welcome to the WALTEC community, innovative solutions for the glass industry!

OUR VALUES —

RELIABLE BY TRADITION

At WALTEC we practice the highest standards of health and safety and migrate this into our produces and services. We recognize fully our responsibility towards our employees and society. We act accordingly. We believe that good and long term relationships do make the difference, we treat each other and all our business partners with respect and care.

Our company offers continuous learning and improvement, ongoing apprenticeship and continuous education is part of our company philosophy. We offer young people the chance to develop and improve themselves through an integrated, practical on the job trainings concept.

We believe that only motivated and skilled employees are capable of delivering “TOP” performance to our customers. Our decisions are guided by the principle that we should empower our people so that they can transfer our world class technology knowledge into solutions that help our friends in the glass industry to cope with today’s complex challenges.

We feel responsible for our products, our people, the ongoing and exciting innovation path, our nature and your process and success!

Our family tradition and heritage safeguards these values across the globe and that’s why we are proudly saying; “reliable by tradition”.

tailor-made SOLUTIONS –

INCREASE YOUR EFFICIENCY

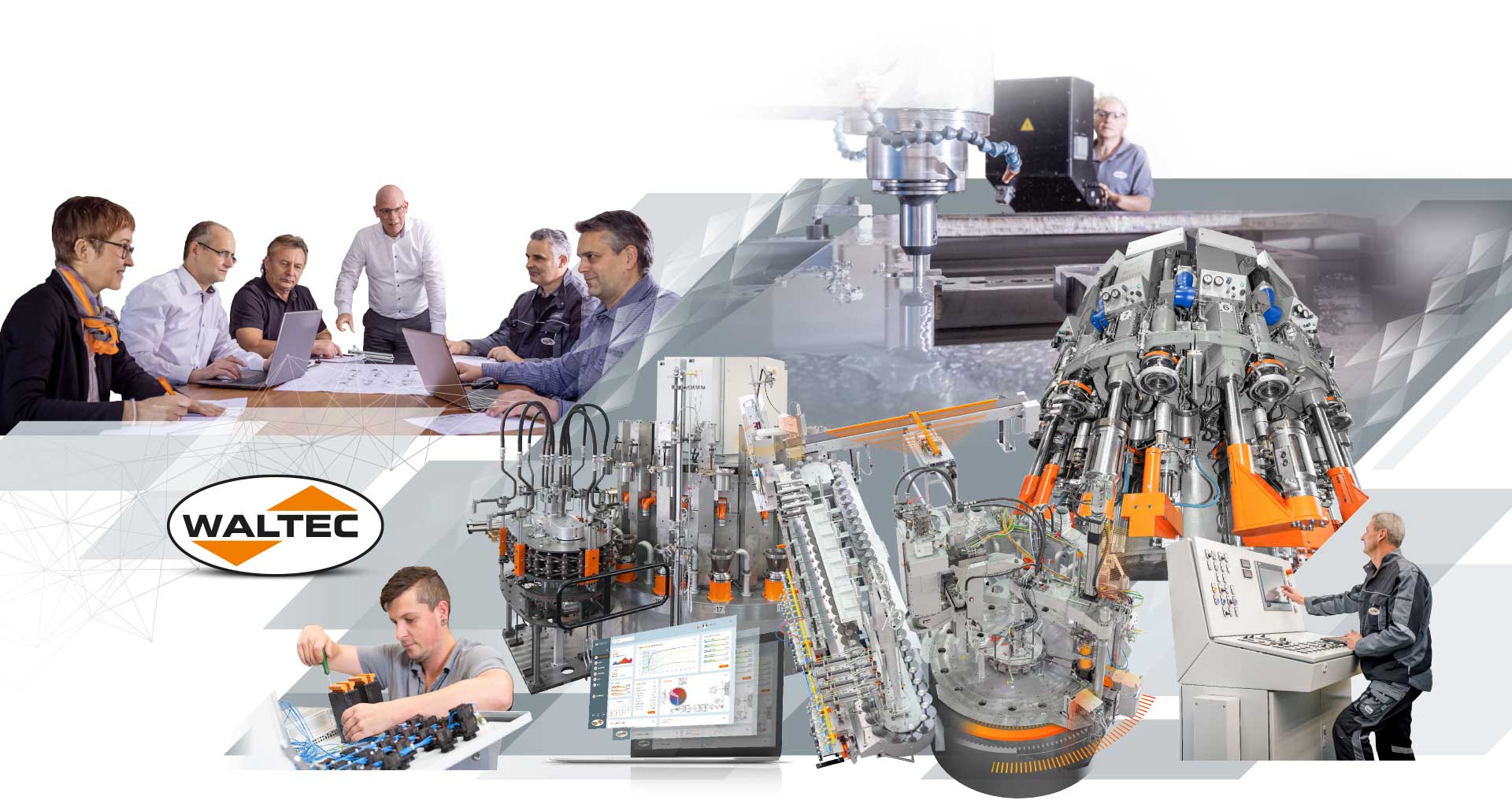

We create and build new technology solutions. Every inquiry is unique and will always be handled by a multidisciplinary project team of WALTEC specialists. Contemporary software solutions analyzing and optimizing data and efficiency are accompanied by self-engineered artificial intelligence. We deliver tailor-made processes and machine designs to comply with Industry 4.0 standards and even beyond.

Process design and

machine development

All activities, from design to manufacturing, up to customer delivery and the start of operations, are executed by our qualified team of specialists. WALTEC offers a one-stop customer approach. The risk of any third-party failure is eliminated and the highest quality and true customer satisfaction are guaranteed.

Quality through

in-house manufacturing

Process design and

machine development

We create and build new technology solutions. Every inquiry is unique and will always be handled by a multidisciplinary project team of WALTEC specialists. Contemporary software solutions analyzing and optimizing data and efficiency are accompanied by self-engineered artificial intelligence. We deliver tailor-made processes and machine designs to comply with Industry 4.0 standards and even beyond.

Quality through

in-house manufacturing

All activities, from design to manufacturing, up to customer delivery and the start of operations, are executed by our qualified team of specialists. WALTEC offers a one-stop customer approach. The risk of any third-party failure is eliminated and the highest quality and true customer satisfaction are guaranteed.

After-sales-service and

productivity Support

Once in operation, our service is always at your side to help. Increasing output, reducing cost, or ensuring continuity of operations and minimal downtimes: our after-sales team supports your process 24/7. Additional on-line troubleshooting, as well as direct communication with our experts, is highly appreciated by all of our customers. WALTEC safeguards spare parts availability and ensures supply reliability through its network of certified suppliers. A continuous flow of new and innovative components to drive productivity improvements and to upgrade older machine configurations forms the backbone of this service.

Commissioning and

start-up service

Our experienced engineers and fitters install the production lines at the desired customer location. A smooth and fast launch of operations is ensured by commissioning and start-up hand in hand. A full on-site operator training program comes as part of the deal. WALTEC also offers a fully remote-controlled commissioning service.

optimized solutions for

your sustainable glass production

Internationality is our maxim, support without limit for highest requirements is our motto. As a global player, our machines and services are available world-wide. Therefore, it is important to us that our customers have a personal contact in their vicinity.

Please contact us, so that we can provide your personal contact in your vicinity.

WALTEC MASCHINEN GMBH

Kronacher Strasse 2A

96352 Wilhelmsthal/ Steinberg

Germany

CHINA

INDIA

CIS

INDONESIA

SOUTH-EAST EUROPE

CENTRAL & SOUTH AMERICA

SOUTH-EAST ASIA

AFRICA

WNEWS – Update your competences

Join WNEWS INNOVATIONS and stay up to date with our latest technologies! Strengthen your business competence, benefit from special offers and discover the next level of productivity and maximum efficiency!

English

English Dansk

Dansk Español

Español پارسی

پارسی Français

Français हिन्दी; हिंदी

हिन्दी; हिंदी Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Română

Română Русский

Русский Slovenščina

Slovenščina Svenska

Svenska 中文(简体)

中文(简体)