![]()

DINCOLO AȘTEPTĂRILE CLIENȚILOR:

CALITATE ÎMBUNĂTĂTĂTĂ ȘI ECONOMII DE ENERGIE

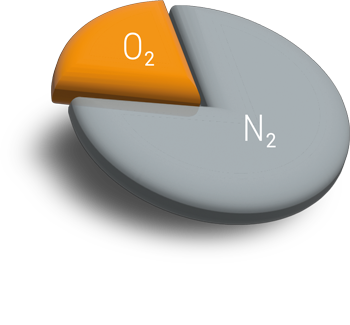

Un proces tradițional de lustruire la foc se bazează pe fuziunea gazelor precum gazul natural, metan sau propan cu aer comprimat și arderea acestui amestec până la temperatura potrivită de aprindere. Acest proces duce la un nivel ridicat de risipă de energie: Azotul din aerul comprimat trebuie încălzit!

O altă problemă importantă din punct de vedere energetic este fluxul continuu de articole, trecând printr-un tunel de arzătoare acționate permanent pe ambele părți. Astfel, flăcările nu sunt direcționate numai către suprafețele articolelor, dar ard și o cantitate mare de energie prețioasă pentru spațiile dintre articolele din sticlă.. Acest lucru duce la o pierdere inutilă și costisitoare de energie.

O altă problemă importantă din punct de vedere energetic este fluxul continuu de articole, trecând printr-un tunel de arzătoare acționate permanent pe ambele părți. Astfel, flăcările nu sunt direcționate numai către suprafețele articolelor, dar ard și o cantitate mare de energie prețioasă pentru spațiile dintre articolele din sticlă.. Acest lucru duce la o pierdere inutilă și costisitoare de energie.

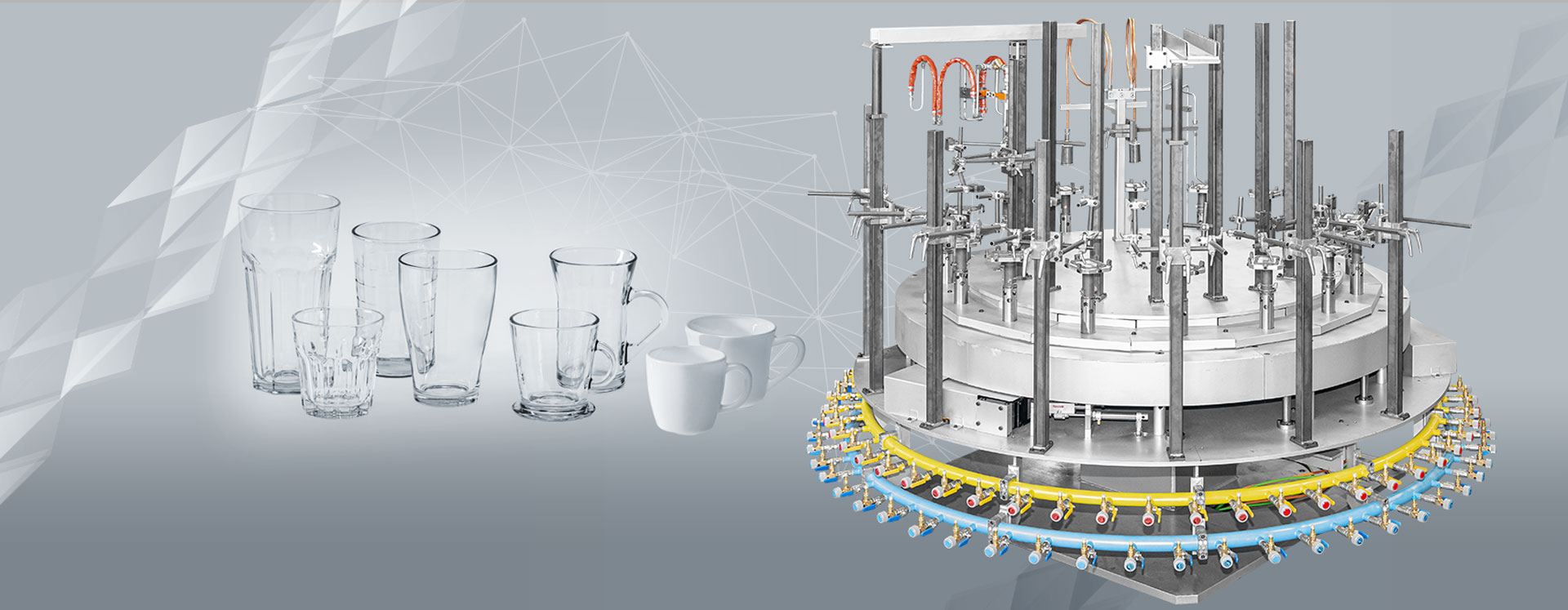

WALTECLiniile de lustruire la foc servo-alimentate cu tehnologia inovatoare a arzătoarelor de urmărire generează economii de energie, îmbunătățiți calitatea produsului și sprijiniți funcționalitatea multi-produs.

WALTEC a înlocuit aerul comprimat cu oxigen – economisind aproximativ 30% a gazelor de ardere. Sistemul inovator de urmarire a arzatorului scade consumul de gaz cu altul 50%.

WALTECmașinile de șlefuit servo-alimentate de ultimă generație cu gaz și oxigen, precum și tehnologia arzătoarelor de urmărire oferă economii complete de energie de până la 80%.

Tehnologia Servo Drive sincronizează complet transportul articolului și rotația axului cu arzătoarele de urmărire și garantează o lustruire de înaltă precizie, eficientă din punct de vedere energetic și cea mai bună calitate posibilă a suprafeței.

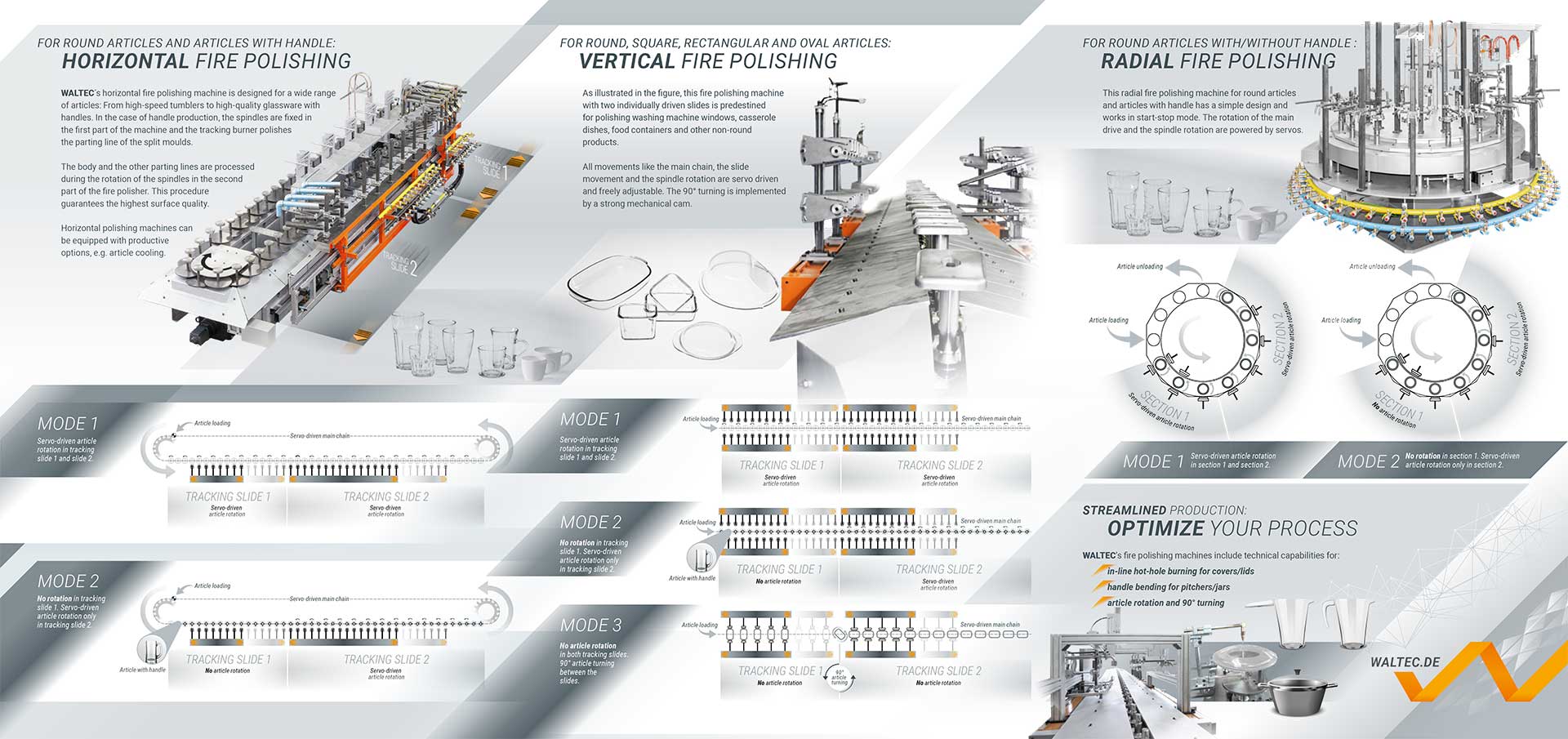

PENTRU ARTICOLE ROTUNDE ȘI ARTICOLE CU MÂNER:

ORIZONTALĂ LUCRAREA INCENDIILOR

WALTECMașina orizontală de lustruit cu foc este proiectată pentru o gamă largă de articole: De la pahare de mare viteză la sticlărie de înaltă calitate cu mânere. În cazul producţiei de mâner, fusurile sunt fixate în prima parte a mașinii, iar arzătorul de urmărire lustruiește linia de despărțire a matrițelor despicate.

Corpul și celelalte linii de despărțire sunt prelucrate în timpul rotației fusurilor din a doua parte a polizorului de foc. Această procedură garantează cea mai înaltă calitate a suprafeței.

Mașinile de lustruit orizontal pot fi echipate cu opțiuni productive, de exemplu. răcirea articolului.

MOD 1

Rotirea articolului cu servomotor în diapozitivul de urmărire 1 si aluneca 2.

MOD 2

Fără rotație în diapozitiv de urmărire 1. Rotirea articolului cu servomotor numai în diapozitivul de urmărire 2.

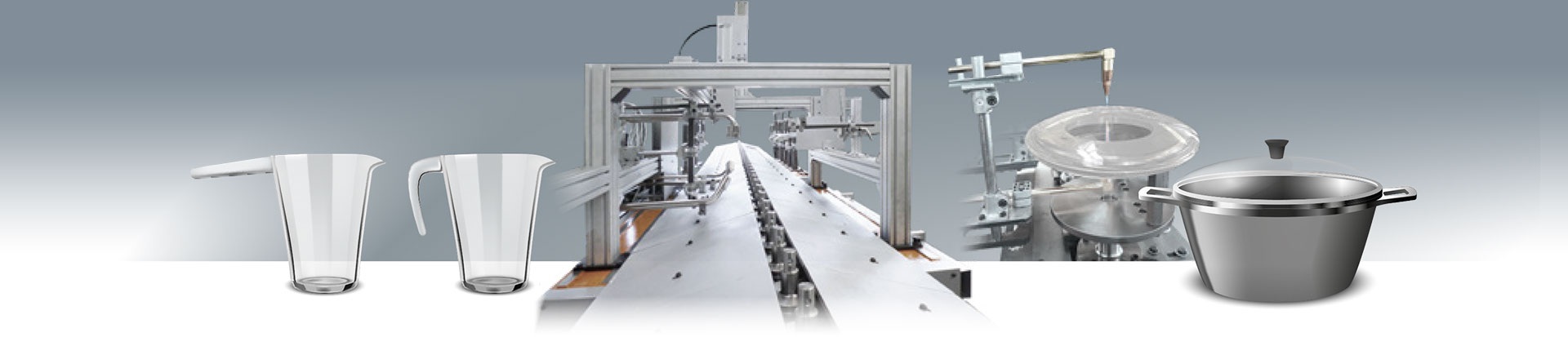

PENTRU ROUND, PĂTRAT, ARTICOLE DREPTUNGULARE SI OVALE:

VERTICAL LUCRAREA INCENDIILOR

După cum este ilustrat în figură, această mașină de lustruit cu foc cu două glisiere acționate individual este predestinată pentru lustruirea geamurilor mașinii de spălat, caserole, recipiente pentru alimente și alte produse nerotunde.

Toate mișcările ca lanțul principal, miscarea glisantei si rotatia axului sunt servo actionate si reglabile liber. Rotirea la 90° este implementată de o camă mecanică puternică.

MOD 1

Rotirea articolului cu servomotor în diapozitivul de urmărire 1 si aluneca 2.

MOD 2

Fără rotație în diapozitiv de urmărire 1. Rotirea articolului cu servomotor numai în diapozitivul de urmărire 2.

MOD 3

Fără rotație de articole în ambele diapozitive de urmărire. 90° rotirea articolului între diapozitive.

PENTRU ARTICOLE ROTUNDE CU/FĂRĂ MÂNER:

RADIAL LUCRAREA INCENDIILOR

Această mașină de lustruit cu foc radial pentru articole rotunde și articole cu mâner are un design simplu și funcționează în modul start-stop. Rotația motorului principal și rotația axului sunt alimentate de servo.

MOD 1

Rotirea articolului cu servomotor în secțiune 1 si sectiunea 2.

MOD 2

Fără rotație in sectiune 1. Rotirea articolului cu servomotor numai în secțiune 2.

RAȚIONATĂ PRODUCȚIE:

OPTIMIZAȚI PROCESUL DVS

WALTECmașinile de lustruit la foc includ capacități tehnice pentru:

Ardere cu gaură fierbinte în linie

pentru capace/capace

Îndoirea mânerului

pentru ulcioare/borcane

Rotirea articolelor

și rotire la 90°

English

English Dansk

Dansk Español

Español پارسی

پارسی Français

Français हिन्दी; हिंदी

हिन्दी; हिंदी Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Română

Română Русский

Русский Slovenščina

Slovenščina Svenska

Svenska 中文(简体)

中文(简体)