![]()

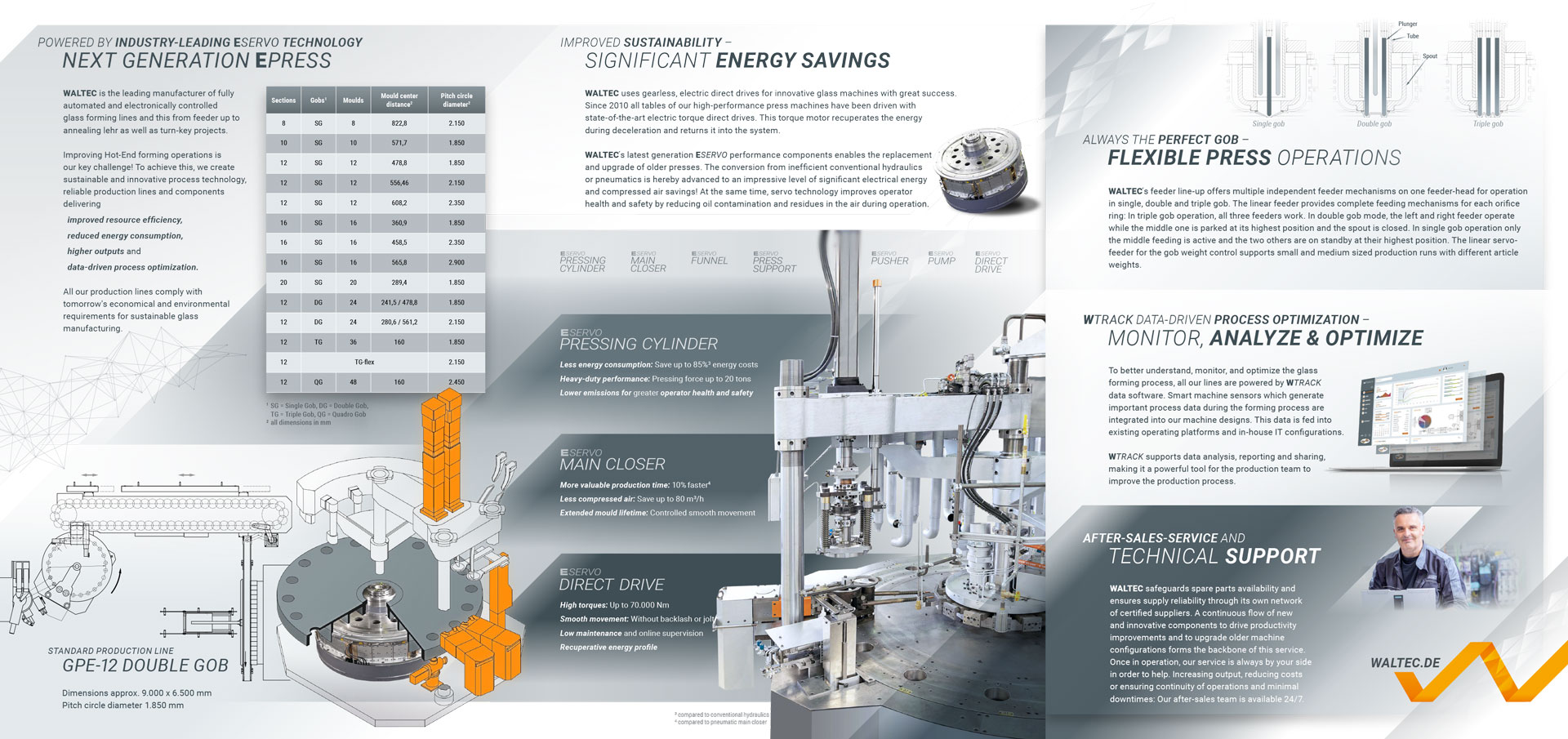

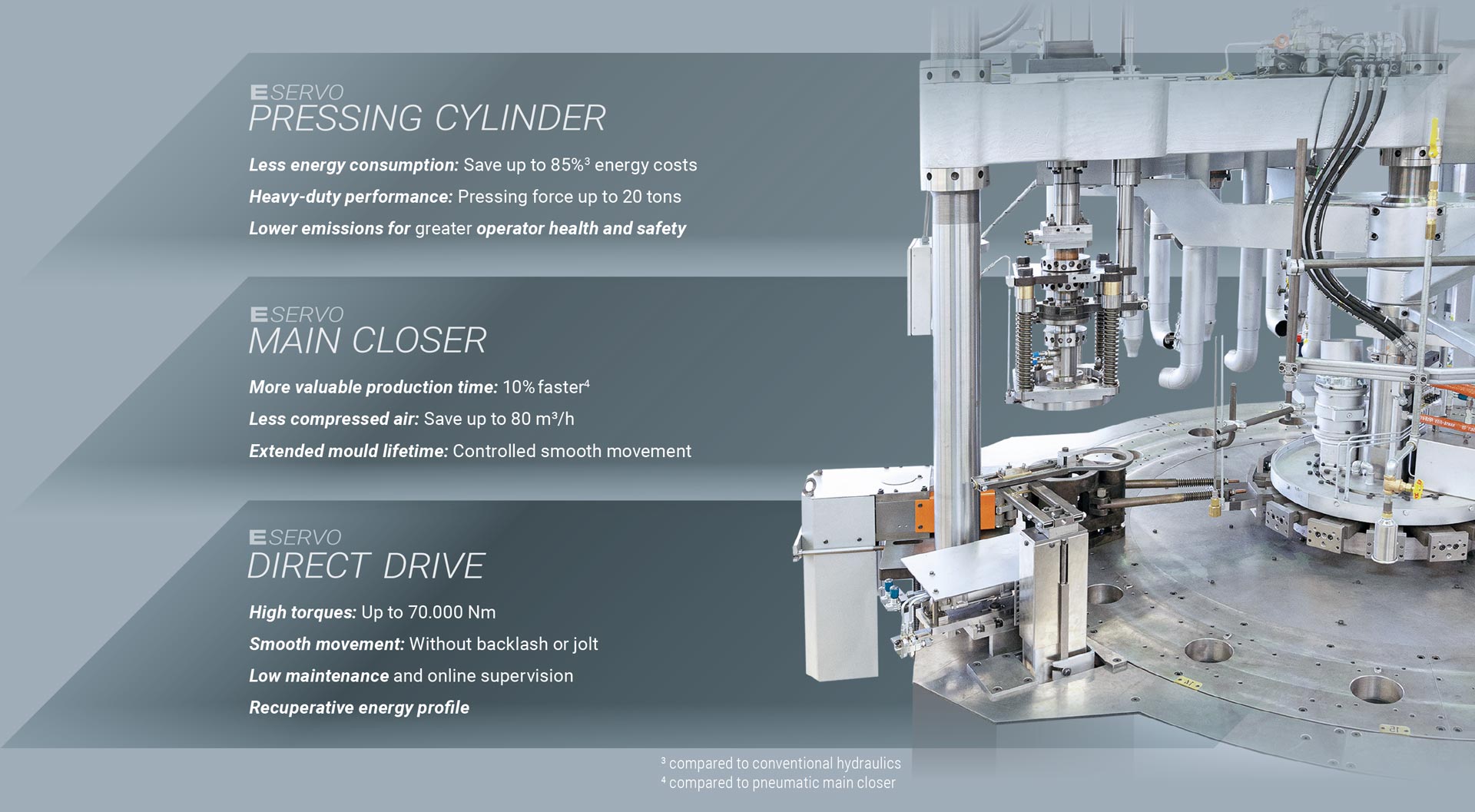

POWERED BY INDUSTRY-LEADING ESERVO TECHNOLOGY:

NEXT GENERATION EPRESS

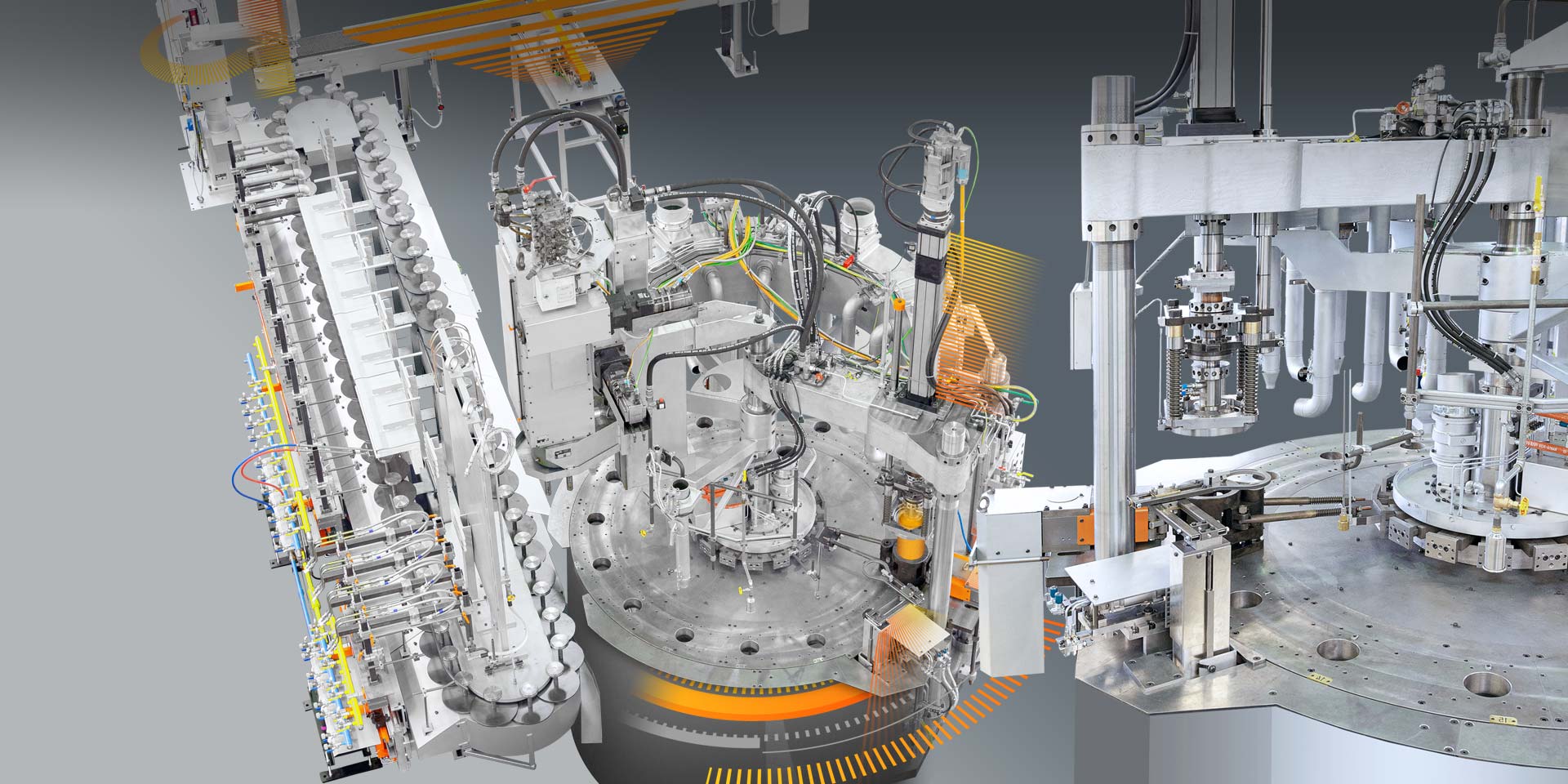

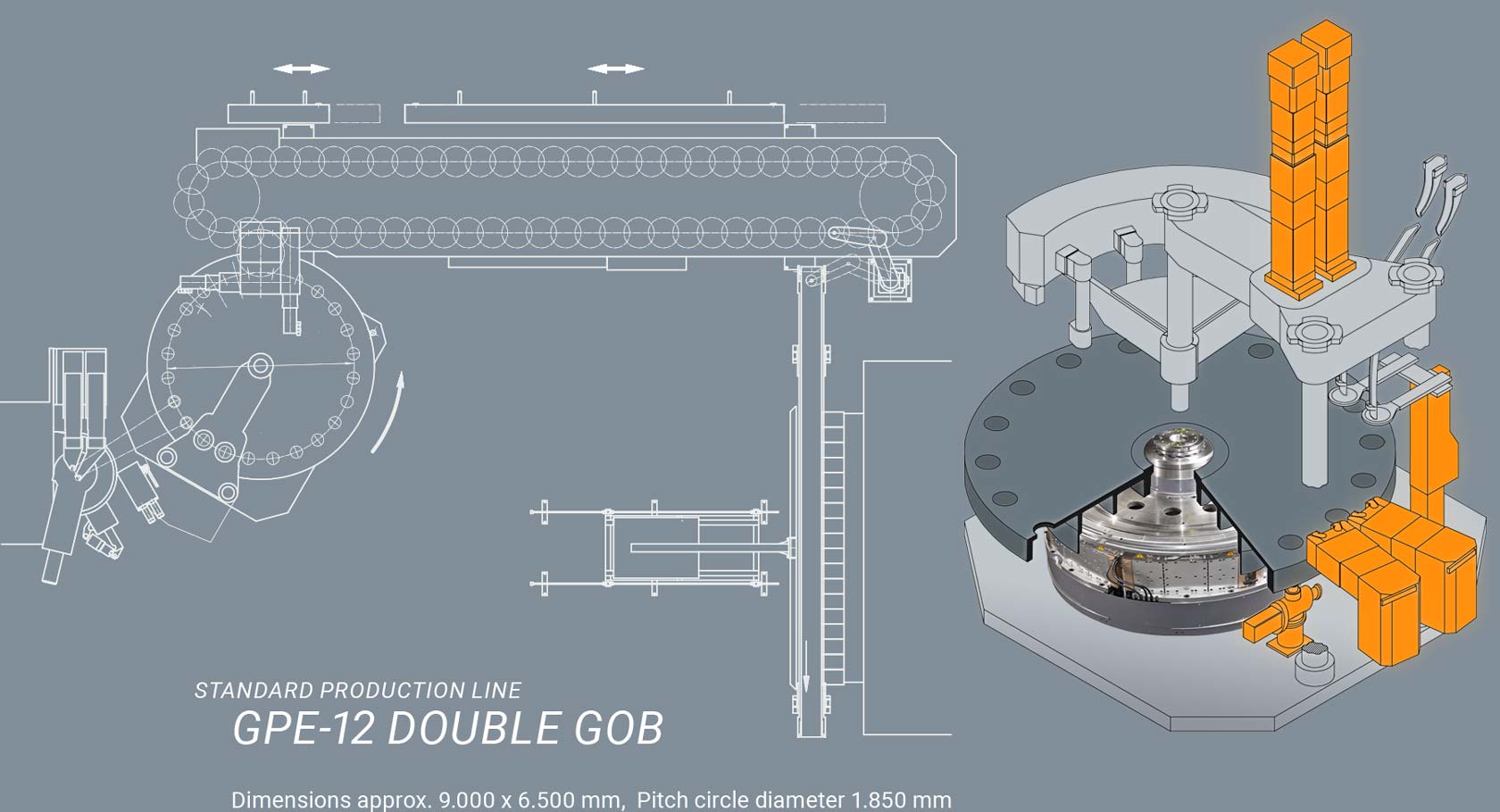

WALTEC is the leading manufacturer of fully automated and electronically controlled glass forming lines and this from feeder up to annealing lehr as well as turn-key projects. Improving Hot-End forming operations is our key challenge! To achieve this, we create sustainable and innovative process technology, reliable production lines and components delivering

- improved resource efficiency,

- reduced energy consumption,

- higher outputs and

- data-driven process optimization.

All our production lines comply with tomorrow’s economical and environmental requirements for sustainable glass manufacturing.

IMPROVED SUSTAINABILITY –

SIGNIFICANT ENERGY SAVINGS

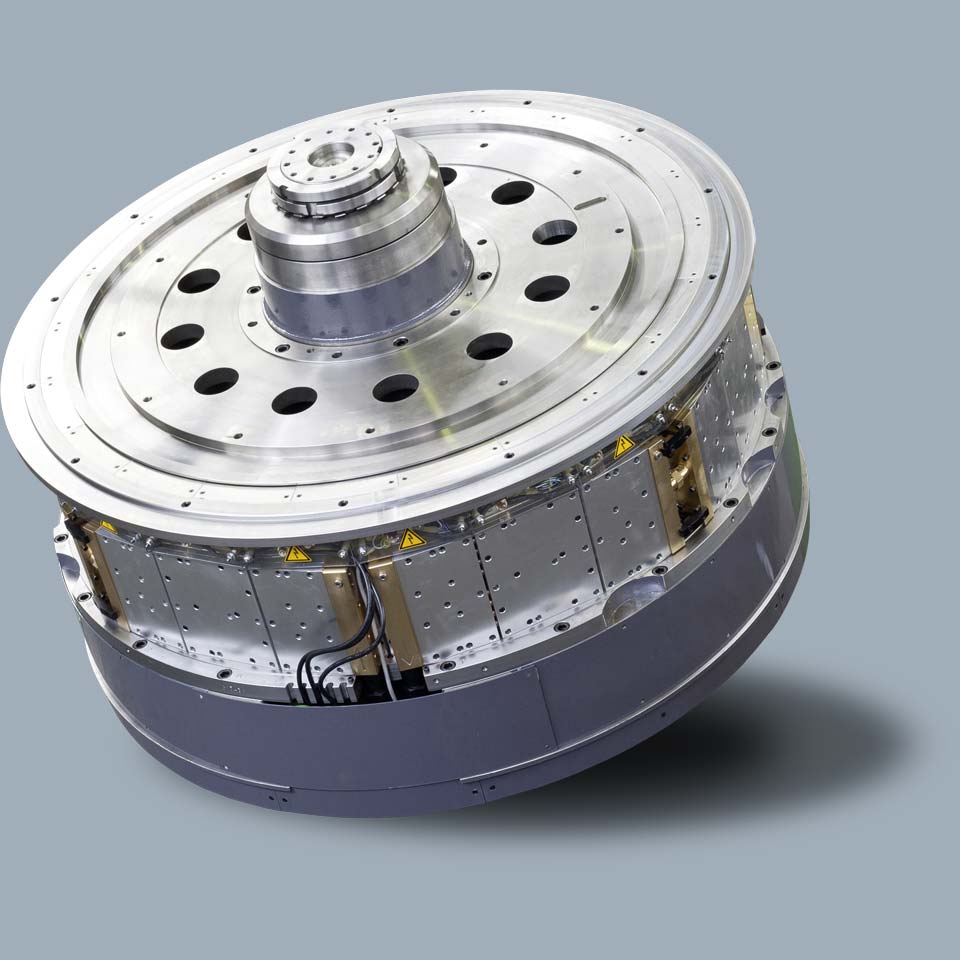

WALTEC uses gearless, electric direct drives for innovative glass machines with great success. Since 2010 all tables of our high-performance press machines have been driven with state-of-the-art electric torque direct drives. This torque motor recuperates the energy during deceleration and returns it into the system.

WALTEC‘s latest generation ESERVO performance components enables the replacementand upgrade of older presses. The conversion from inefficient conventional hydraulics or pneumatics is hereby advanced to an impressive level of significant electrical energy and compressed air savings! At the same time, servo technology improves operator health and safety by reducing oil contamination and residues in the air during operation.

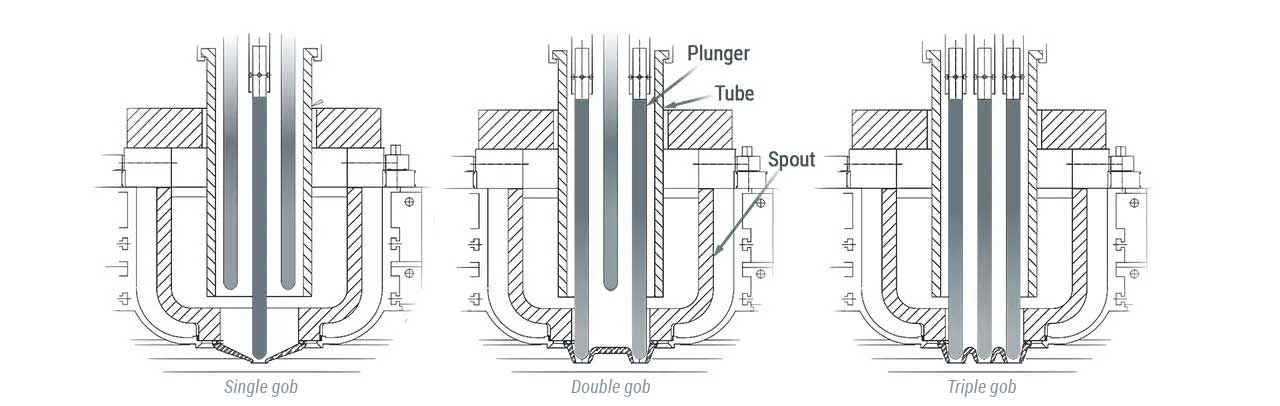

ALWAYS THE PERFECT GOB –

FLEXIBLE PRESS OPERATIONS

WALTEC‘s feeder line-up offers multiple independent feeder mechanisms on one feeder-head for operation in single, double and triple gob. The linear feeder provides complete feeding mechanisms for each orifice ring: In triple gob operation, all three feeders work. In double gob mode, the left and right feeder operate while the middle one is parked at its highest position and the spout is closed. In single gob operation only the middle feeding is active and the two others are on standby at their highest position. The linear servo-feeder for the gob weight control supports small and medium sized production runs with different article weights.

WTRACK DATA-DRIVEN PROCESS OPTIMIZATION –

MONITOR, ANALYZE & OPTIMIZE

To better understand, monitor, and optimize the glass forming process, all our lines are powered by WTRACK data software. Smart machine sensors which generate important process data during the forming process are integrated into our machine designs. This data is fed into existing operating platforms and in-house IT configurations.

WTRACK supports data analysis, reporting and sharing, making it a powerful tool for the production team to improve the production process.

AFTER-SALES-SERVICE AND

TECHNICAL SUPPORT

WALTEC safeguards spare parts availability and ensures supply reliability through its own network of certified suppliers. A continuous flow of new and innovative components to drive productivity improvements and to upgrade older machine configurations forms the backbone of this service. Once in operation, our service is always by your side in order to help. Increasing output, reducing costs or ensuring continuity of operations and minimal downtimes: Our after-sales team is available 24/7.

English

English Dansk

Dansk Español

Español پارسی

پارسی Français

Français हिन्दी; हिंदी

हिन्दी; हिंदी Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Română

Română Русский

Русский Slovenščina

Slovenščina Svenska

Svenska 中文(简体)

中文(简体)