![]()

Sustainable Hot End process optimization by

ESERVO PERFORMANCE COMPONENTS

EFFICIENCY & SUSTAINABILITY

Economics by WALTEC

Far more precise and repeatable servo movements will result in higher efficiencies, too. At the same time servo technology improves operator health and safety through the reduction of in-air oil pollution and residues during operation. The game-changing ESERVO performance components are only consuming power when needed and through this generating substantial savings in energy and compressed air.

Discover the most sustainable and efficient solutions for your hot end press process. We are building production lines, machines, components and intelligent data processing software to make this happen. How can we help you? Your needs are our challenge – let´s get connected and replace your inefficient conventional hydraulics and old energy intensive pneumatics.

NEXT GENERATION

SERVO TECHNOLOGY

Start saving money now and boost the output of your press process up to 20%, save energy up to 80%, reduce compressed air up 130 m³/h and improve your efficiency into a new dimension!

We developed a new range of Industry 4.0 compatible ESERVO performance components with the intention of upgrading your press lines whilst improving their cost-sustainabililty footprint, extending their life-cycle and so saving on capex.

ESERVO performance components from WALTEC are compatible with almost all in-market press lines, inclusive those from other press suppliers. ESERVO performance components can be used to upgrade your existing press line.

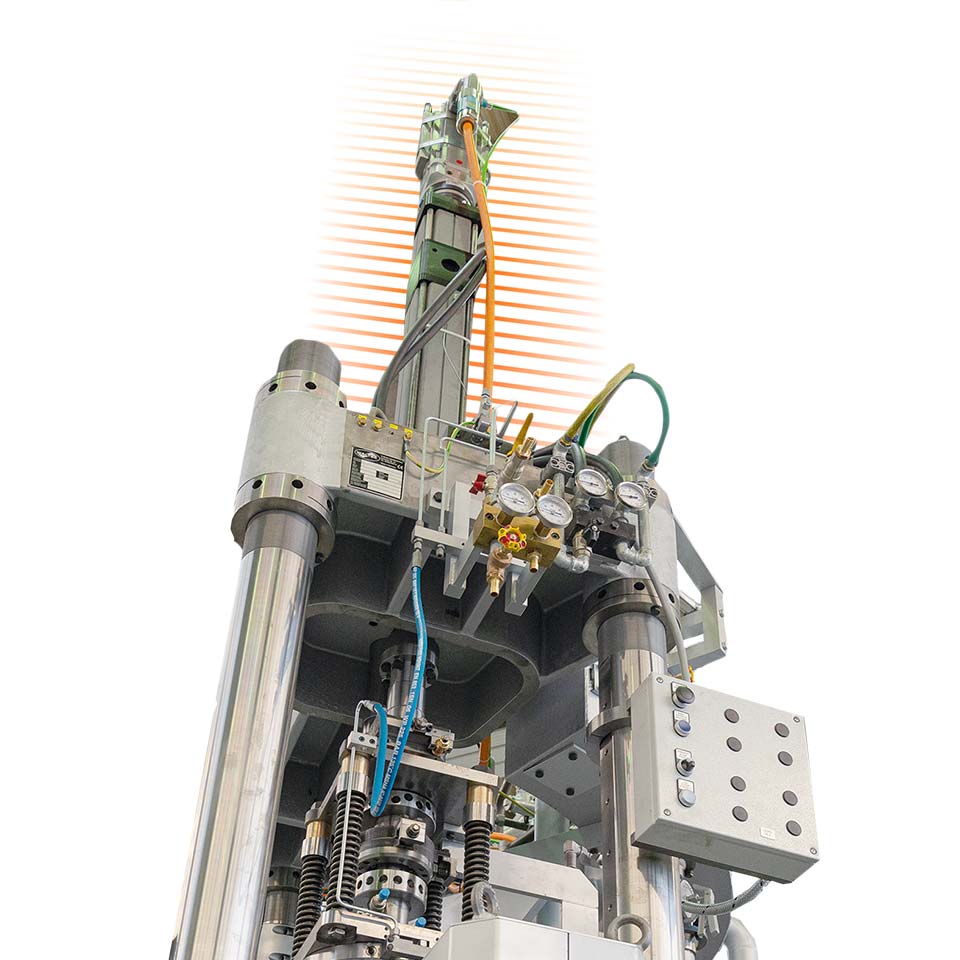

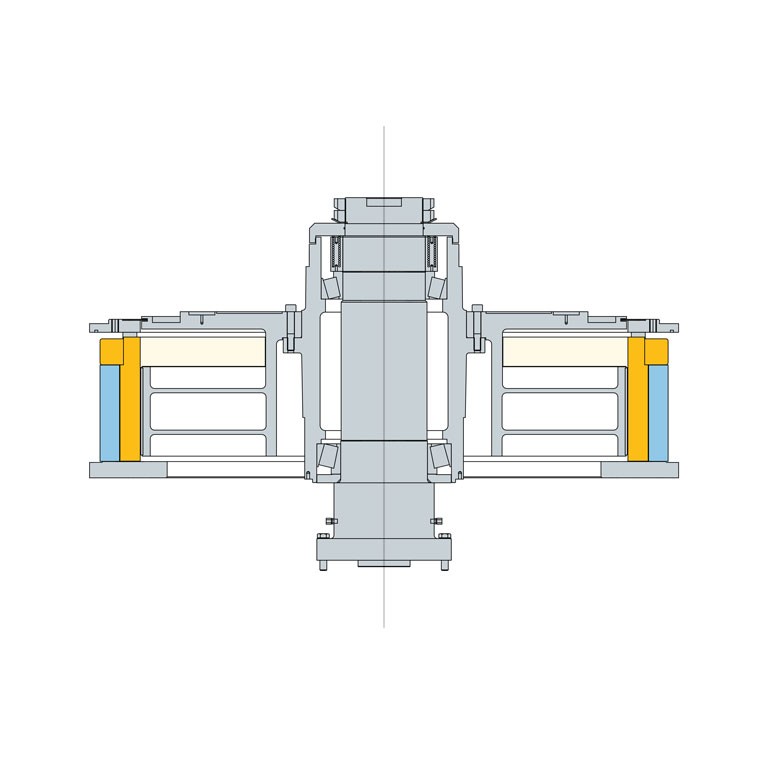

PRESSING CYLINDER

- Less energy consumption:

save up to 85% energy costs compared to conventional hydraulics - Lower emissions (operator health) and less danger (fire):

no oil needed and higher safety as zero oil inside - Heavy duty performance:

pressing force up to 20 tons - Extended lifetime:

including proprietary technology

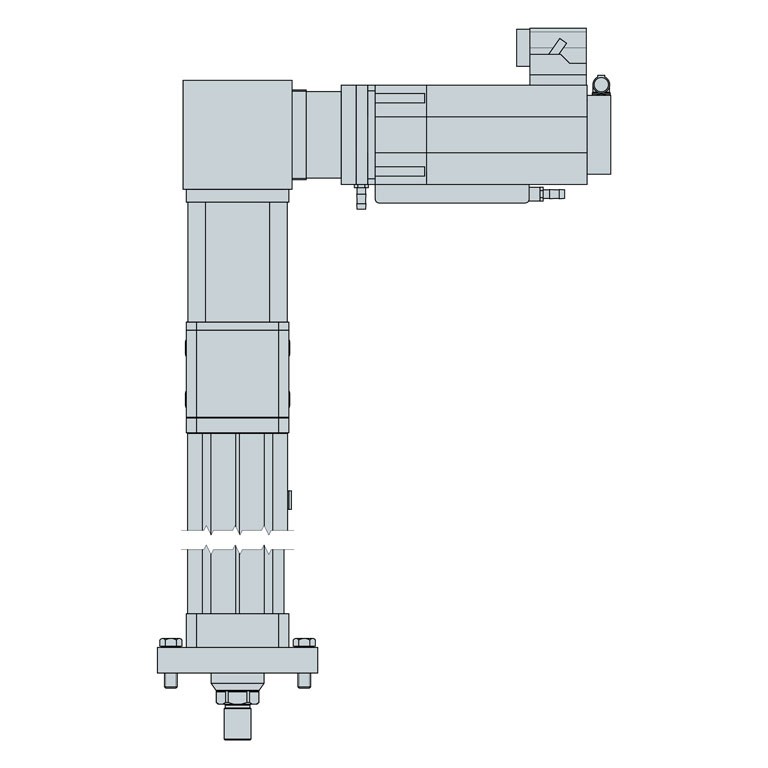

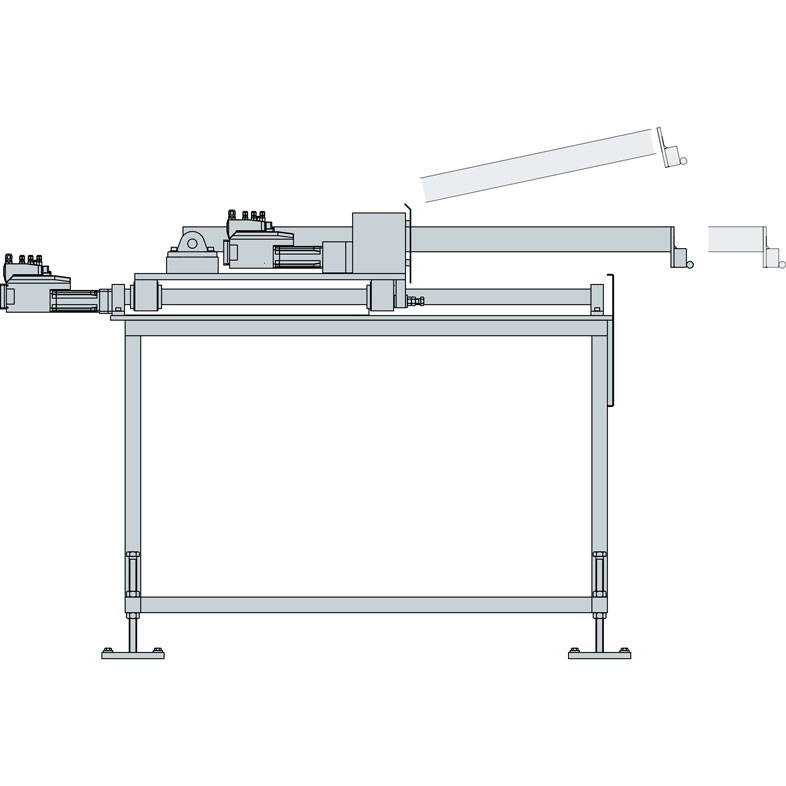

MAIN CLOSER

- Speed up press cycles:

save up to 100 ms valuable cycle time

- Less compressed air:

save up 80 m³/h - Extended mold lifetime:

controlled and smooth movement

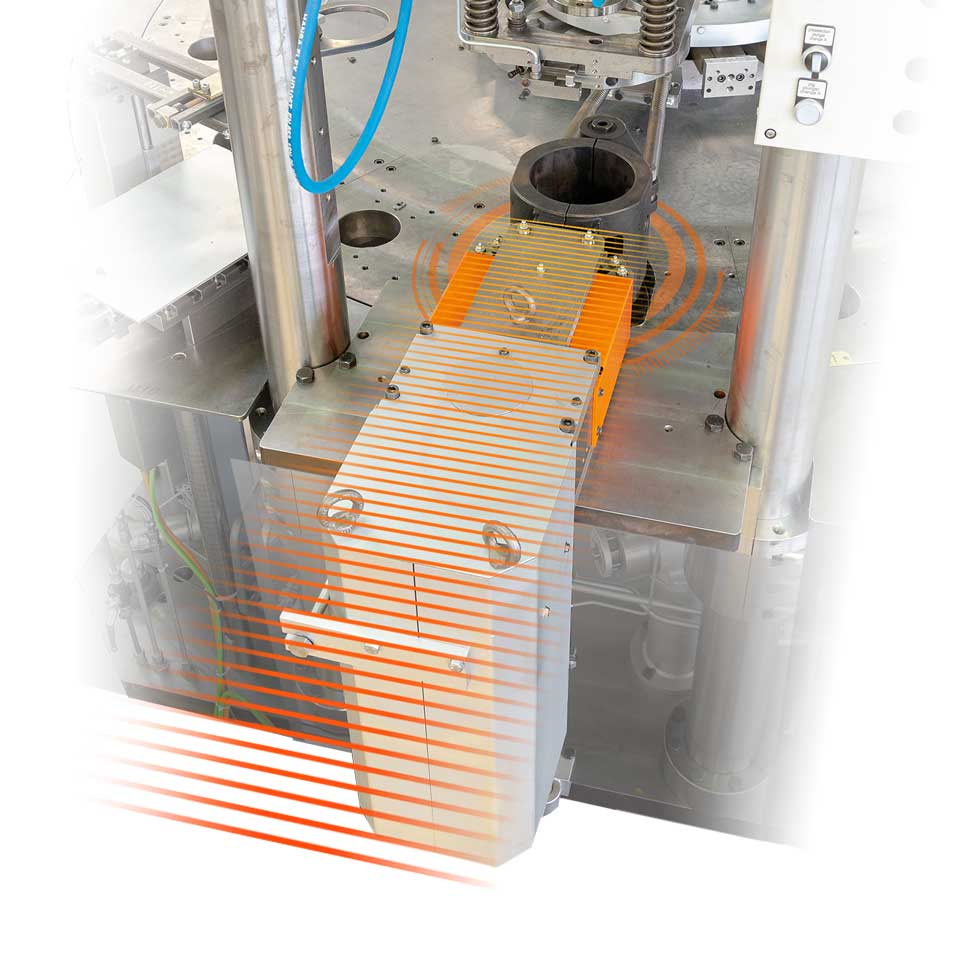

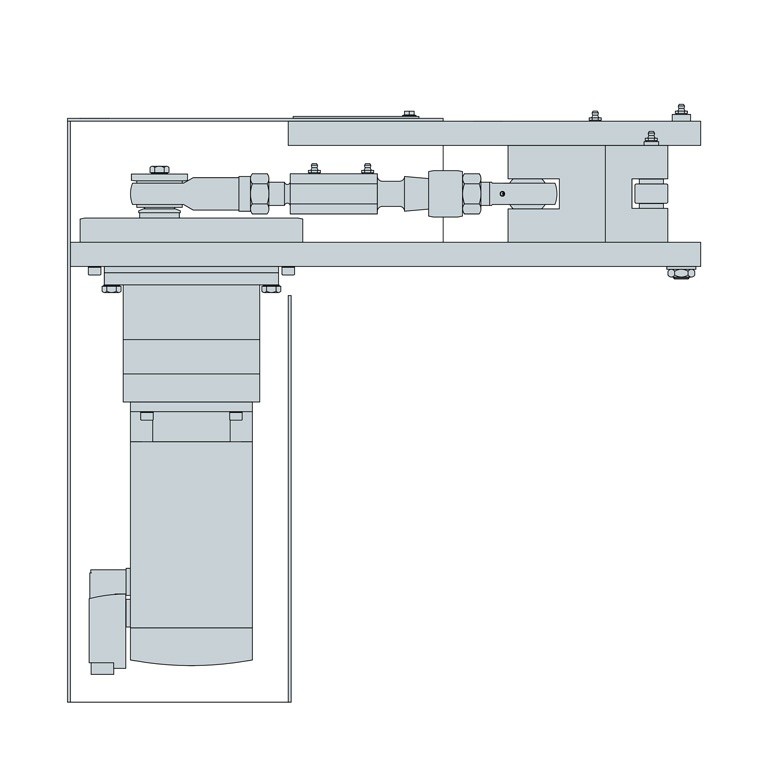

PUSHER

- Less energy consumption:

save up to 10 m³/h compressed air - Improved glass surface quality:

variable speed control and soft touch function - Less maintenance needed:

due to contemporary machine design

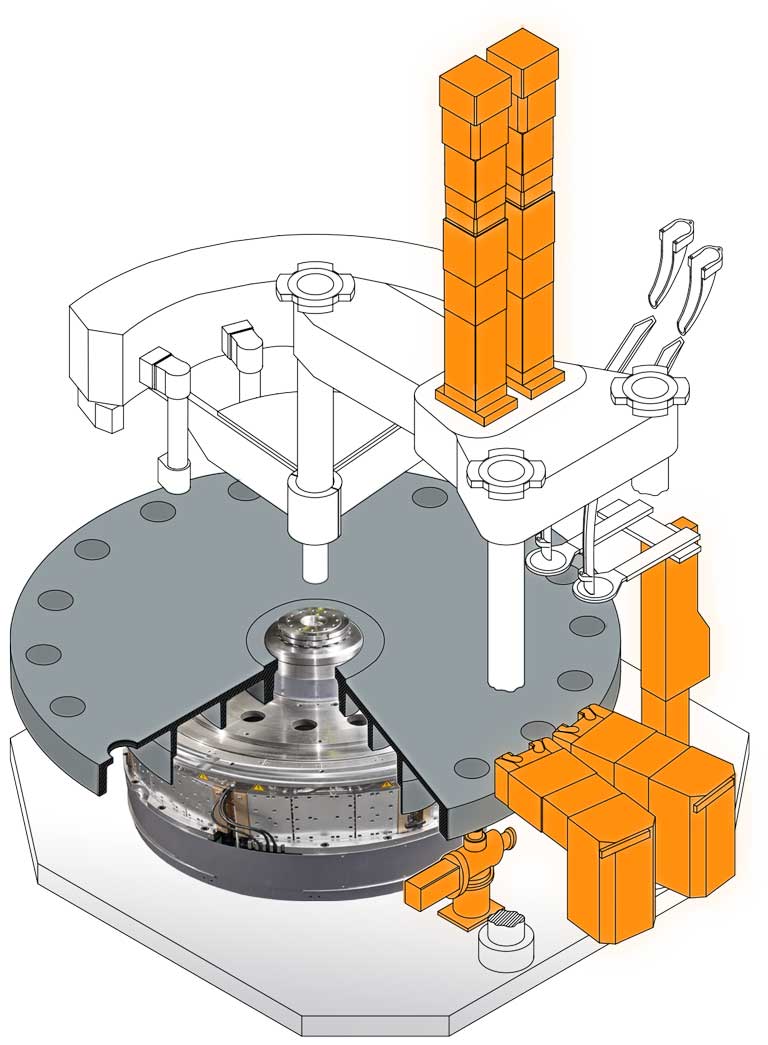

DIRECT DRIVE

- High torques:

up to 70.000 Nm - Short table indexing times:

up to 0,25 seconds - Smooth movement:

free from backlash and jolt - Online drive supervision and

low maintenance

The information in this document contains general and technical capabilities of this technology. Savings and other performance values reflect estimates according to our own best knowledge. These represent an average of single and double gob configurations operating in medium gob size settings. Compressed air savings are calculated based on 5 bar working pressure. Therfore the required performance characteristics need to be specified individually at the time of contract. WALTEC reserves the right to make technical modifications at any point in time and adjust it’s information accordingly without prior notice. Our employees are gladly at your disposal for individual consultation.

SUSTAINABLE AND INCREASINGLY DIGITALISED CONCEPT –

INNOVATING IN UNISON

WALTEC‘s partnership with SIEMENS features benefits for Polish manufacturer TREND GLASS

English

English Dansk

Dansk Español

Español پارسی

پارسی Français

Français हिन्दी; हिंदी

हिन्दी; हिंदी Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Română

Română Русский

Русский Slovenščina

Slovenščina Svenska

Svenska 中文(简体)

中文(简体)