![]()

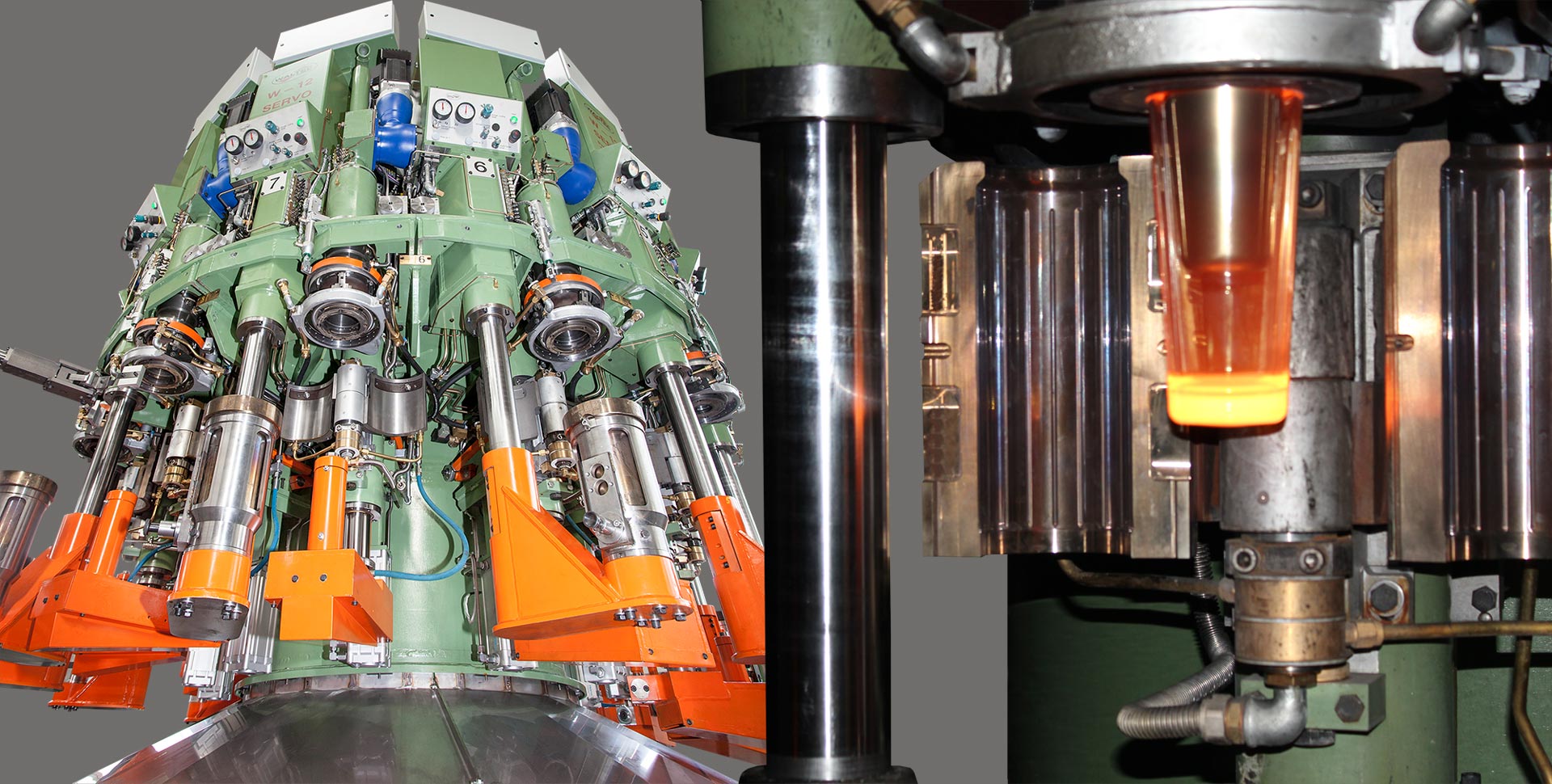

Our press-blow machine is the consequent further development of the conventional process, where high-quality hollow glasses are produced by pre-forming, pre-pressing and blowing, both in rotation blown-ware operation and in non-rotation blown-ware operation.

Contrary to the well-known machine concept, where the process movements, such as pre-pressing and others, are realised pneumatically, WALTEC replaced the pneumatic drives, which could only be adjusted in a dissatisfying way, by the latest servo technology in all ranges. That means, all movements of pressing plungers, pre-mould and article support are realised with servo technology. For the first time the press-blow process becomes transparent, can be controlled exactly and is reproducible.

Thus, all movements have a very high repeat accuracy, resulting in high process stability.

Furthermore, WALTEC met the requirements of the market for bigger products. Our machine is fit to produce articles with the following maximum dimensions.

- max. diameter: 160 mm

- max. height: 350 mm

In connection with our burn-off as well as laser crack-off machines we enable our customers to produce stem ware in high quality, increasing the range of application and consequently the efficiency of the machine essentially.

Due to the modular construction technique our press-blow machines are available with all common numbers of stations:

W1 / W2 / W3 → W24

patented technology from WALTEC

servo controlled process movements:

- servo driven plunger

- servo driven blank mould

- servo driven bottom

- servo driven neck ring rotation

- servo driven bottom rotation

All Process-parameters are readable, recordable and repeatable to the point:

- better quality products

- reduced job-change time

- drastically reduced ramp up time for new articles

simple electronic control structure:

- field-bus servo drives

- no control cabinet on top of machine

- full functionality of the disassembled single section

- simple rotary slip ring for AC/DC- and data transmission

energy consumption and environment:

- fan air blank mould cooling

- no more huge pneumatic cylinders

- protects operators and environment

- drastically reduced pneumatic exhaust air

- saves up to 150.000 kWh per year for compressed air

WNEWS – Update your competences

Join WNEWS INNOVATIONS and stay up to date with our latest technologies! Strengthen your business competence, benefit from special offers and discover the next level of productivity and maximum efficiency!

English

English Dansk

Dansk Español

Español پارسی

پارسی Français

Français हिन्दी; हिंदी

हिन्दी; हिंदी Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Română

Română Русский

Русский Slovenščina

Slovenščina Svenska

Svenska 中文(简体)

中文(简体)