![]()

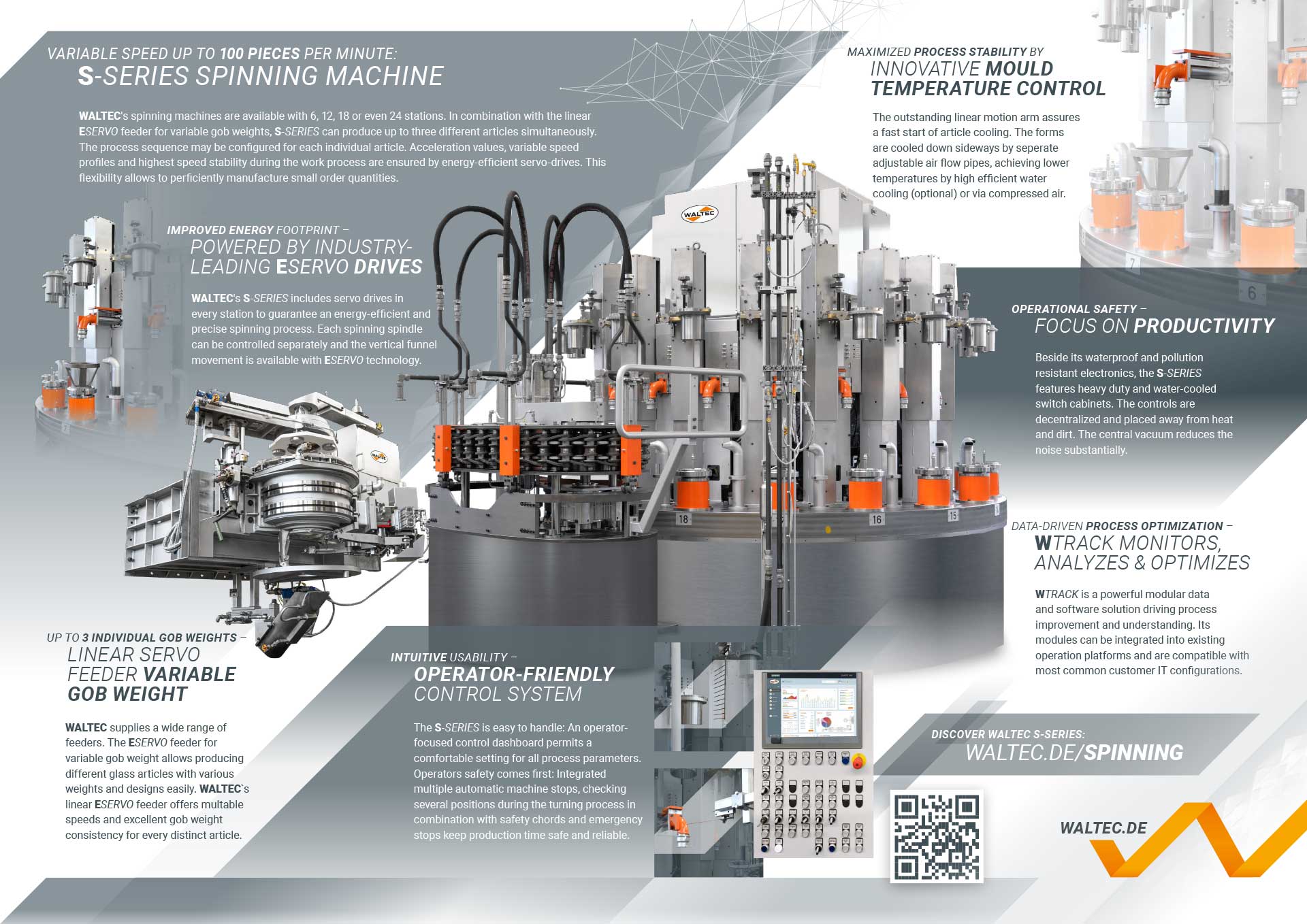

S-SERIES SPINNING MACHINE

ENERGY-EFFICIENT ESERVO TECHNOLOGY – UP TO 100 PIECES PER MINUTE:

VARIABLE SPEED, MORE PRODUCTIVITY AND MAXIMAL STABILITY

WALTEC‘s spinning machines are available with 6, 12, 18 or even 24 stations.In combination with the linear ESERVO feeder for variable gob weights, S-SERIES can produce up to three different articles simultaneously.

The process sequence may be configured for each individual article. Acceleration values, variable speed profiles and highest speed stability during the work process are ensured by energy-efficient servo-drives. This flexibility allows to perficiently manufacture small order quantities.

IMPROVED ENERGY FOOTPRINT –

POWERED BY INDUSTRY-

LEADING ESERVO DRIVES

WALTEC‘s S-SERIES includes servo drives in every station to guarantee an energy-efficient and precise spinning process. Each spinning spindle can be controlled separately and the vertical funnel movement is available with ESERVO technology.

UP TO 3 INDIVIDUAL GOB WEIGHTS –

Linear Servo Feeder

VARIABLE GOB WEIGHT

WALTEC supplies a wide range of feeders. The ESERVO feeder for variable gob weight allows producing different glass articles with various weights and designs easily. WALTEC`s linear ESERVO feeder offers multable speeds and excellent gob weight consistency for every distinct article.

MAXIMIZED PROCESS STABILITY –

INNOVATIVE MOULD

TEMPERATURE CONTROL

The outstanding linear motion arm assures a fast start of article cooling. The forms are cooled down sideways by seperate adjustable air flow pipes, achieving lower temperatures by high efficient water cooling (optional) or via compressed air.

OPERATIONAL SAFETY –

FOCUS ON PRODUCTIVITY

AND SUSTAINABILITY

Beside its waterproof and pollution resistant electronics, the S-SERIES features heavy duty and water-cooled switch cabinets. The controls are decentralized and placed away from heat and dirt. The central vacuum reduces the noise substantially.

INTUITIVE USABILITY –

OPERATOR-FRIENDLY

CONTROL SYSTEM

The S-SERIES is easy to handle: An operator-focused control dashboard permits a comfortable setting for all process parameters. Operators safety comes first: Integrated multiple automatic machine stops, checking several positions during the turning process in combination with safety chords and emergency stops keep production time safe and reliable.

DATA-DRIVEN PROCESS OPTIMIZATION –

WTRACK MONITORS,

ANALYZES AND OPTIMIZES

WTRACK is a powerful modular data and software solution driving process improvement and understanding. Its modules can be integrated into existing operation platforms and are compatible with most common customer IT configurations.

Schedule your individual S-series presentation –

discover the most productive spinning process from WALTEC

Schedule your individual online presentation and discover the outstanding features of our S18 spinning machine. Meet our engineers and ask whatever you want to know. Explore every detail and embark on a groundbreaking journey to highest efficiency, reliability and quality of your hot end press process. Let’s get together!

English

English Dansk

Dansk Español

Español پارسی

پارسی Français

Français हिन्दी; हिंदी

हिन्दी; हिंदी Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Română

Română Русский

Русский Slovenščina

Slovenščina Svenska

Svenska 中文(简体)

中文(简体)